Metallurgical Lab Services

Using state-of-the-art equipment, National Kwikmetal Services on-site Metallurgists perform metallurgical testing in our in-house Metallurgical Lab. NKS Metallurgists are problem solvers, always ready to consult with customers on challenges they face when choosing the proper grade of stainless, aluminum or electrical steels. Using ASTM testing standards, National Kwikmetal Services Metallurgists will determine the proper grade to ensure clients receive the appropriate grade for their application.

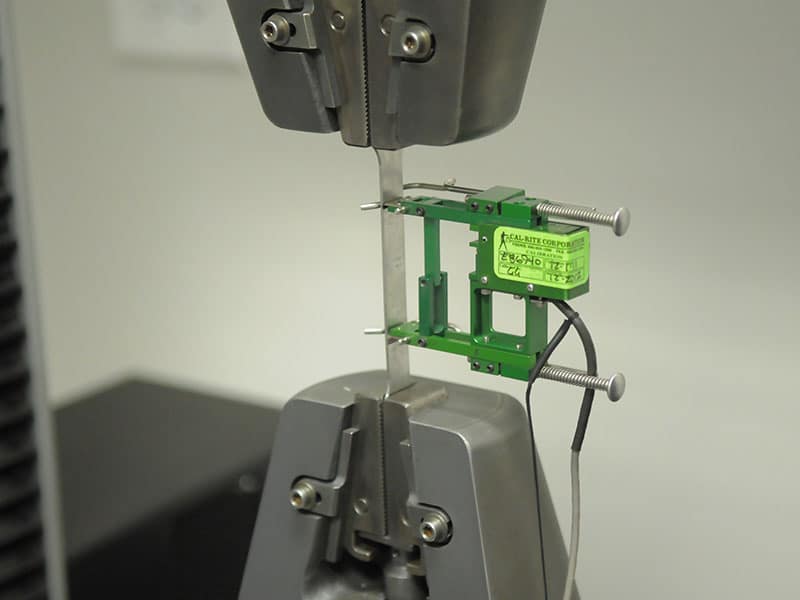

Educated in Tensile, Rockwell Hardness, Bend, Surface Finish, Electrical/Magnetic and Chemical testing, our Metallurgists use Metallurgical Laboratory equipment such as tension testers and metal analyzers to provide valuable test data.

- Tensile -Test includes tensile, yield and elongation (specify test direction). Thickness range annealed and tempered – 0.006″ to 0.187″ Per: ASTM E8 (steels); AST M B557 (aluminum)

- Rockwell Hardness Testing – ASTM E18. Rockwell A, B and C and Rockwell Superficial T and N scales. Test includes average of 3 reading – conversions per ASTM E140. Thickness minimum annealed and tempered – 0.010″.

- Bend – ASTM E290:

- Testing conducted with the bend parallel or perpendicular to rolling direction (specify test direction). 180 Degree bend thickness maximum (annealed 0.150″, tempered 0.050″).

- Surface Finish Testing – ASME B46.1:

- Ra, Rz, Rq – Please specify test direction. No thickness restrictions – sample must be flat.

- Chemistry (200, 300 & 400 series stainless steels) Per ASTM A751 and ASTM E1086

- Chemistry (1000, 2000, 3000, 5000, 6000 & 7000 series Aluminums) Per ASTM E1251

- Chemical analysis is performed using optical emission spectroscopy (OES).

- Let us advise you on your electrical steel core loss, coating composition and coating resistance requirements.